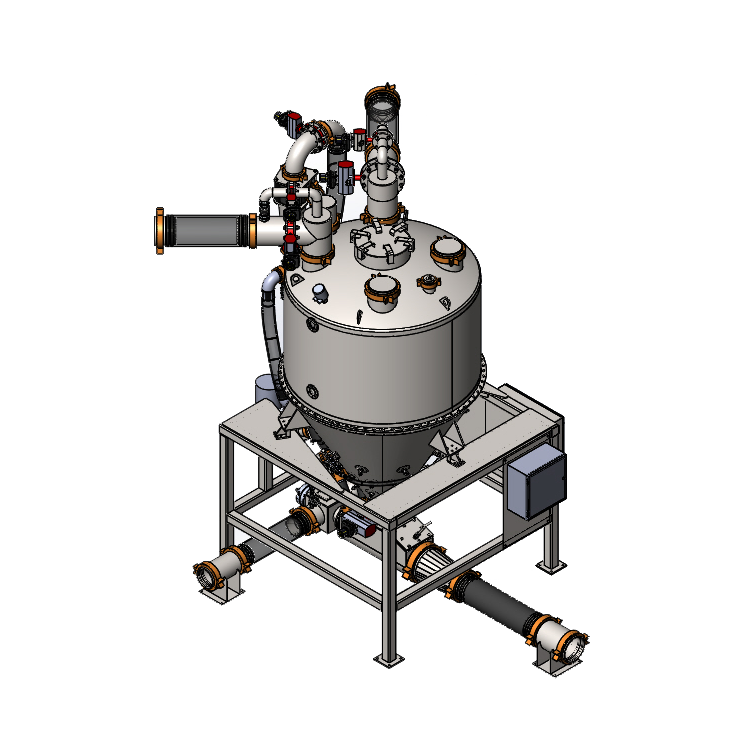

Blending and conveying powdered materials from multiple sources? Then Cyclonaire CB Series Blend-Veyors are for you. With Blend-Veyors, you can blend and convey two or more materials in one unit for greater efficiency and less product degradation. These products feature vacuum-loaded, semi-dense phase blending and conveyance with a capacity up to 80 TPH. Blend-Veyors use a single 15 PSI positive displacement blower for vacuum-pressure conveying at low line velocities (<2000–4000 fpm) and high material to- air ratios (50–20), reducing material degradation and abrasive line wear.

As the load cycle begins, the suction valve opens while the discharge valve is closed. The air pressure generates a vacuum by patented venturi action. As the vacuum increases in the transfer vessel, the separately valved dual inlets open until the desired weight is reached.

Upon completion of the load/blend cycle, the inlet and suction valves close and the discharge valve opens. The same positive air supply which created the vacuum is used to push the material into the discharge manifold where it is fluidized for semi conveying—minimizing particle degradation, reducing line wear and increasing system efficiency.

Easily retrofitted to existing storage for up to eight sources

Designed for a wide variety of applications with blending, batching and conveying all in one unit. Provides proprietary combined blending (two or more materials) with semi-dense phase conveying.

Minimize product degradation and line wear.

No Costly Pits — Designed for low head room scenarios.