Cyclonaire’s Turbo-Inductor Systems offer faster unloading from pneumatic trailers and railcars. These self-contained systems work by stepping up to larger diameter convey lines and adding higher volumes of air to the conveyed bulk material – without any modifications to the delivery vehicles.

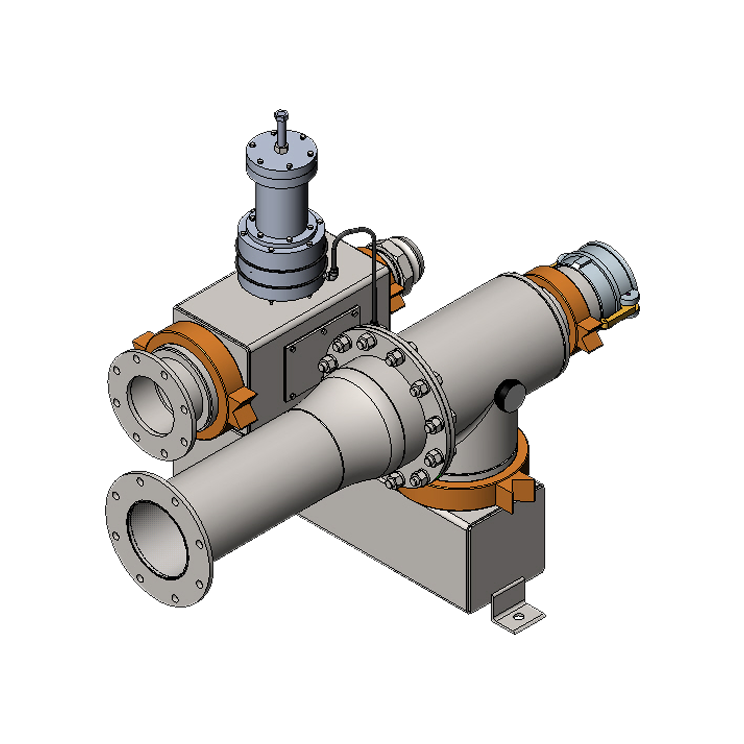

A complete Cyclonaire Turbo-Inductor System includes a Turbo-Inductor, a 15 psig rated blower sized for the application, connecting hoses and optional NEMA 4 type controls enclosure.

In addition to higher product transfer rates, Turbo Inductor systems eliminate the need to use tractor-mounted blowers, thereby saving fuel and wear and tear on the delivery vehicles.

Speeds the unloading of pneumatic trailers and railcars. Increases the conveyable distance between pneumatic trailer or railcar and storage silo or day bin

Blower capacity, air pressure in the lines, and dust collection are all balanced, increasing overall conveying efficiency and eliminating the risk of plugged lines or accidental dust discharge. Operator time is limited to making hose connections, reducing labor costs